Single-Sourcing in Packaging Supply Chains: Unlocking Operational Excellence

In pursuing operational excellence, businesses are increasingly reevaluating their strategies to navigate intricate supply chain dynamics. If your...

2 min read

UFP Packaging Updated on October 28, 2025

As 2025 progresses, the corrugated packaging industry continues to evolve to meet changing market behavior. The sustained growth of e-commerce and increased demand for sustainable practices are two significant factors. From more eco-friendly designs to advanced digital printing, we predict these three trends will shape corrugated packaging throughout 2025.

Retail-ready custom packaging answers major retailers' initiatives to improve efficiency and reduce waste. Popularized by wholesale outlets, retail-ready packaging means the box, tray, sleeve, bin, or other packaging components in which a product is shipped. These packaging components can be placed directly on the shelf upon arrival, eliminating the need for workers to unpack and stock individual products.

This packaging innovation allows employees to move shipments quickly into place and reduce the stocking and handling process, improving efficiency and decreasing waste by utilizing the product's packaging.

Retail-ready packaging allows for easy, eye-catching displays of products. We expect to see it become even more widespread throughout 2025 as retail outlets look to improve operational efficiency and become more eco-friendly.

Examples of retail-ready packaging

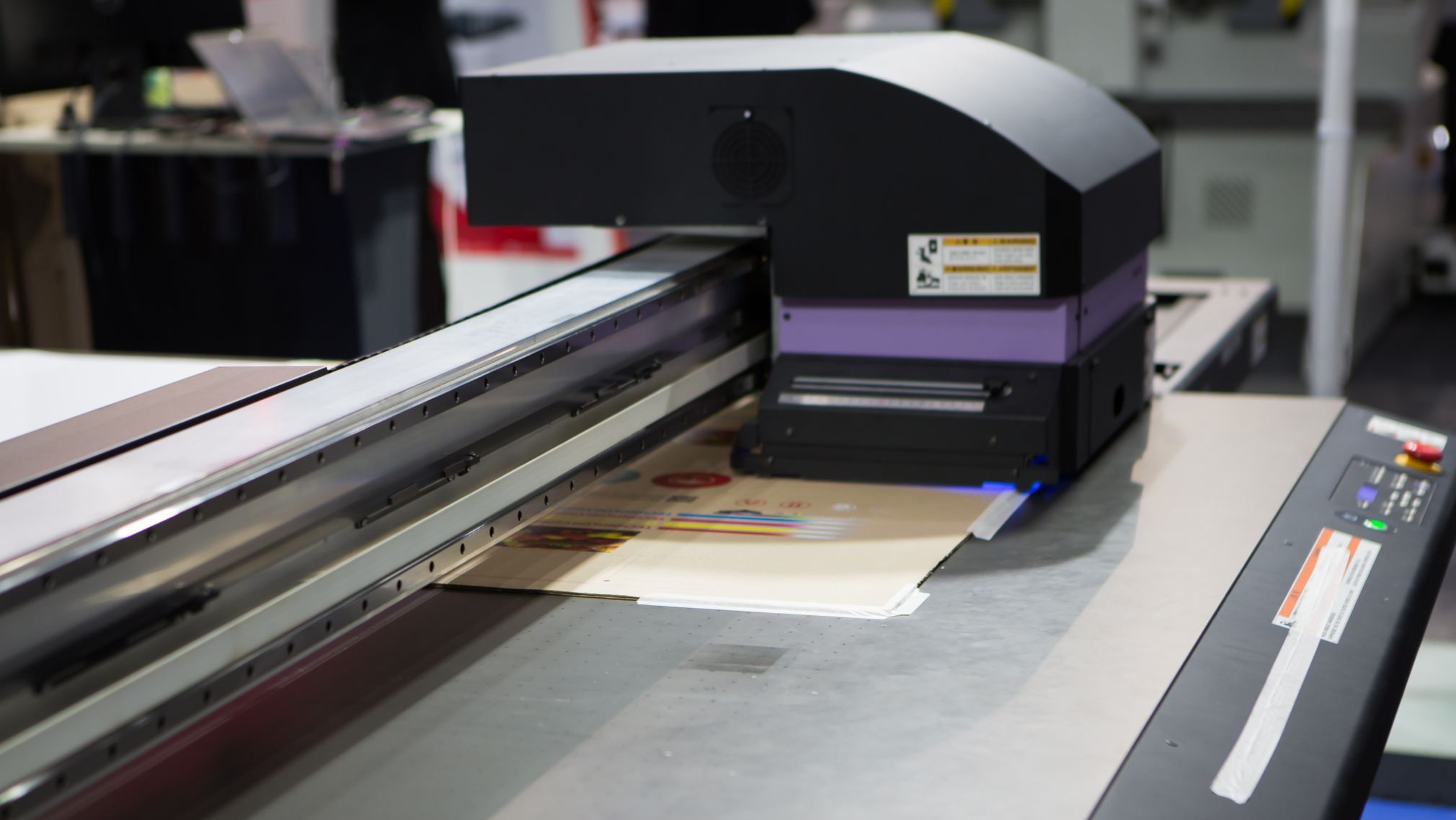

As e-commerce continues to grow and retail-ready packaging is popularized, more detailed, packaging printing designs are required for corrugated. Previously, cardboard or solid fiber substrates supported high-quality, intricate digital printing, while corrugated supported simple branding initiatives with flexographic printing and printing plates. However, digital printing capabilities now allow for printing more elaborate branding directly onto corrugated.

Digital printing enables faster set-up and short-run production capabilities for corrugated, significantly reducing start-up costs for limited-run quantities. Alternatively, flexographic printing uses printing plates and is more cost-effective for high-volume runs. However, it is not as detailed and is better suited for logos, barcodes, and standard branding.

Another emerging corrugated trend due to the sustained growth of the e-commerce market is fit-to-product (FTP) automated packaging. FTP automated packaging enables companies to create customized corrugated shipping boxes tailored precisely to a product's dimensions. This automated technology eliminates material waste through accurate box-sizing and reducing filler material waste. FTP automated packaging benefits large fulfillment companies that distribute products of various shapes and sizes, eliminating the need to have multiple-size box SKUs on hand. As companies focus on more sustainable practices and streamlined operations, fit-to-product technology significantly advances operations.

Custom-sized corrugated boxes made from FTP automated packaging technology

Corrugated packaging in 2025 is about more than protection: efficiency, presentation, customization, and sustainability are key priorities. As trends like retail-ready packaging, high-tech digital printing, and fit-to-product (FTP) automated packaging solutions gain momentum, businesses investing in these innovations will be better positioned to meet retailer demands, cut costs, and reduce negative environmental impact.

As these innovations reshape the corrugated industry, working with a packaging partner that embraces emerging technologies will provide a competitive edge. UFP Packaging has dedicated corrugated manufacturing facilities in Texas, Indiana, and soon the western United States that produce various cost-effective packaging corrugated solutions, including stock corrugated boxes, point-of-purchase displays, bulk bins, e-commerce shippers, retail-ready packaging, custom four-color die-cutting, and corrugated sheets. Our Jeffersonville, Indiana, facility also offers advanced digital printing capabilities for intricate packaging designs and short-run flexibility. Learn more here.

Learn more about our comprehensive corrugated manufacturing capabilities or schedule a consultation to see how UFP Packaging can support your packaging goals in 2025.

Want to receive all of the packaging latest news and insights?

In pursuing operational excellence, businesses are increasingly reevaluating their strategies to navigate intricate supply chain dynamics. If your...

Corrugated and cardboard are often referred to interchangeably but are not the same. While both are paper-based materials and frequently used in...

As solar manufacturing continues to evolve in the United States, so does solar packaging. UFP Packagingis a leading supporter of the thriving solar...