Skid vs Pallet: Understanding the Difference and Why It Matters

Many people use the terms interchangeably, but there is a significant difference between skids and pallets, and knowing the difference can ensure you...

3 min read

UFP Packaging Updated on October 28, 2025

Pallets are essential components in commercial and industrial operations. They are used daily to easily transport goods such as building materials, machinery, furniture, and appliances. However, your business has choices when purchasing pallets: There are new pallets, and there are remanufactured or recycled pallets. Choosing between new and recycled pallets challenges many industries and operational managers. That's why in this article, we will break down the three key reasons why purchasing new pallets may be right for your company.

One of the most significant advantages of new pallets is their reliability. New pallets are built with specific standards to service your business’s precise needs. Exact product measurements for the pallet design are crucial to pallet reliability. Using inadequate wooden boards or improper construction can compromise pallet stiffness. Pallet stiffness ensures symmetrical contact between the product and the pallet deck. Managers should be aware that using thinner boards that are not positioned to support the unit load can cause product damage. New pallets are optimized to meet your shipping and storage requirements. Although you may save money with recycled pallets, they may not be built according to your shipping needs, which could delay shipping, reduce warehouse space, and cause product damage.

Recycled pallets vary in quality and condition based on their prior use and storage conditions. They also could contain hidden defects. According to Michigan State University, protruding, broken, or missing stringers are the most common pallet defects. Check out their article Ten Ways to Spot a Defective Pallet to read about the nine other common pallet defects.

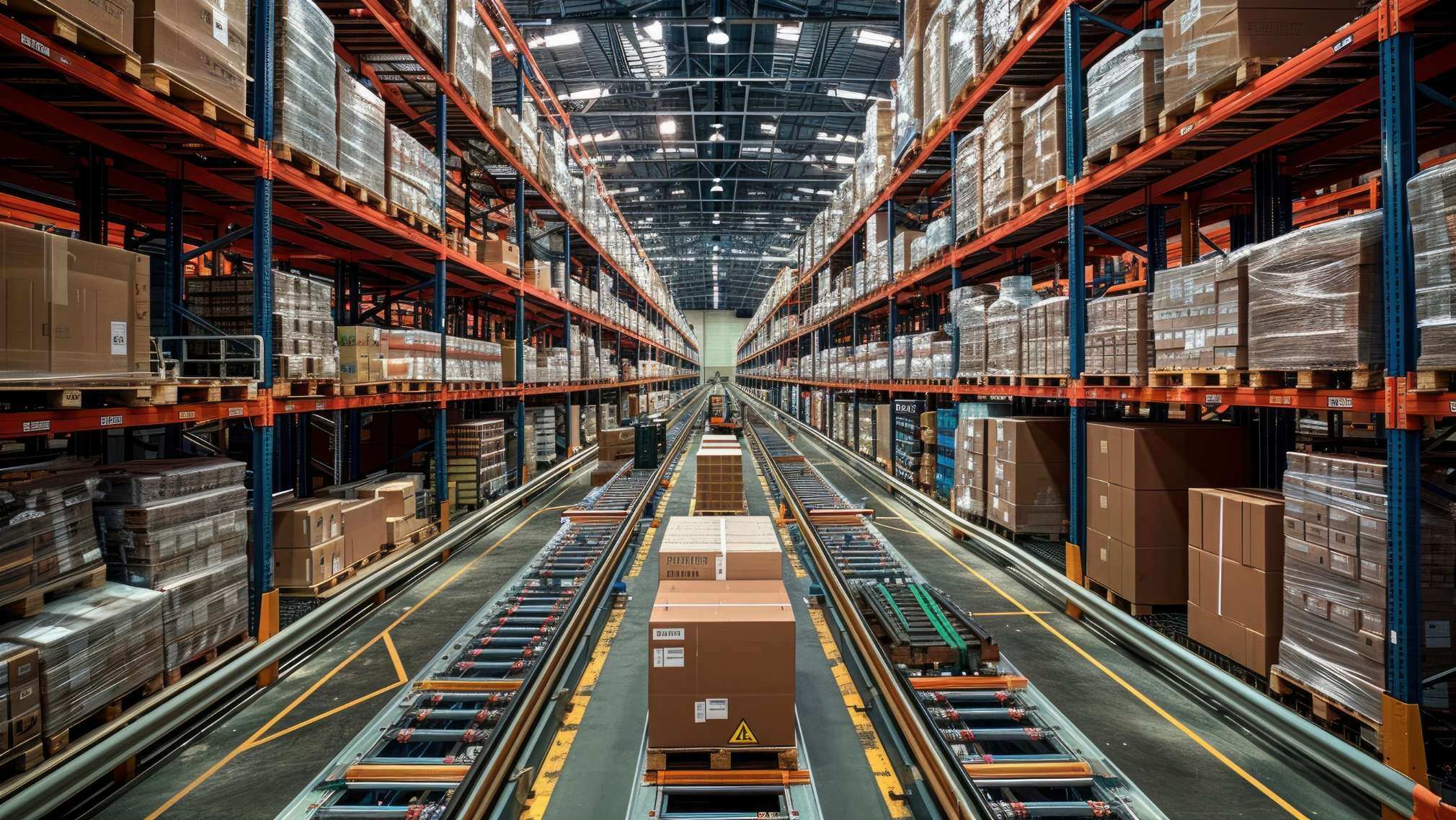

Companies relying on highly efficient, fully automated distribution centers will likely encounter operational challenges from using low-quality pallets. A recent study conducted by Virginia Tech University, Modern Materials Handling, and Peerless Research Group revealed:

The study claims that low-quality pallets are the root cause of issues in highly automated distribution centers due to incompatibility. These unnecessary factors put your valuable products and business at risk, making the use of recycled pallets unpredictable.

That said, recycled pallets can be a suitable solution for certain products and warehouses. To determine if using recycled pallets is a viable solution for your company, consult with a qualified pallet provider. If you are considering purchasing recycled pallets, you should only work with a trusted supplier like PalletOne, which is known for its quality recycled pallets and professionally trained pallet management experts.

PalletOne employees in Siler City, NC restoring a recycled pallet

Another benefit of choosing new pallets over their recycled counterpart is their ability to be customized. Newly manufactured pallets meet your specific needs by constructing the correct type, using precise measurements, and including unique materials to ensure success during use. At UFP Packaging, we have an ISTA-certified testing facility to ensure our pallets are equipped to handle your needs. We also offer design services that can improve existing pallet designs or create new prototypes for testing at our facility.

In contrast, recycled pallets are limited by their existing design and material composition. While a recycler could build custom pallets, it's not common practice. This option may cost as much as a new custom-built pallet. Want the perfect pallet that's specially tailored to your needs? Opt for a new one!

New pallets are also eco-friendly, thanks to sustainable manufacturing practices. At UFP Packaging, we prioritize responsible sourcing of lumber from around the globe. Our commitment to integrity and sustainability extends to our suppliers, whom we closely monitor through regular meetings and on-site visits. Our mill vendors plant more trees than what they harvest, aligning with our core sourcing principles.

For more information on our ESG and sustainability practices, visit our parent website UFP Industries.

Due to their lower price point, recycled pallets appear as an attractive option to many commercial and industrial companies. However, what you aren’t paying for in pallets, you are paying for in risk. Although recycled pallets have their place in the supply chain, they don’t often offer as much value to your company as purchasing new pallets. New pallets provide tremendous amounts of reliability, the highest quality, and options to customize to your specific needs. These are the three key factors that make new pallets a valuable investment for your commercial or industrial operation.

At UFP Packaging, our experienced professionals custom design and manufacture the best pallets for your job. We can build all types of pallets, from basic 48x40 pallets to skids for ultra-heavy, oversized machinery. CP, GMA Standard, Winged & Flush, ISPM-15, and Stringer & Block pallets are also available. We also offer heat-treated pallets for domestic or international shipping. Testing and verification are available upon request via our in-house testing lab, and our national network of pallet manufacturing plants can cover any geographic challenge.

Click here to request a quote or schedule a consultation.

Want to receive all of the latest packaging news and insights?

Many people use the terms interchangeably, but there is a significant difference between skids and pallets, and knowing the difference can ensure you...

The rapid adoption of warehouse automation systems is revolutionizing logistics and supply chain operations worldwide. The growth of e-commerce,...

When selecting pallets for your shipping needs, understanding the full spectrum of options available is crucial for making an informed decision....